Add to Cart

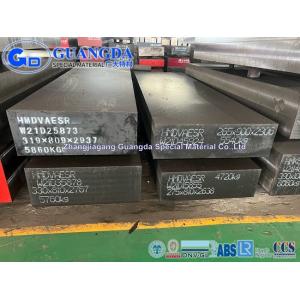

DVA DVA-Nb Hot Work Tool Steel High Impact Toughness And High Isotrapy High Temperature Strength

Hot working die steel is a kind of alloy tool steel used for die forming by pressing solid or liquid metal above phase transition temperature, such as hot forging die steel, die casting die steel, hot stamping die steel, etc. Because the hot working die is in service for a long time under the conditions of high temperature and high pressure and alternating hot and cold, the hot working die steel must have excellent strength and toughness ratio, especially excellent thermal stability and thermal fatigue resistance.

Guangda DVA hot working die steel, with excellent toughness and thermal fatigue resistance, at the same time has good high temperature strength and anti-tempering stability, is a high-quality universal hot working die steel, widely used in the field of hot working.

Chemical composition of Tool and die steel DVA/DVA-Nb

| Grade | C | Si | Mn | P | S | Cr | Mo | V | Nb |

| DVA | 0.35-0.42 | 0.10-0.30 | 0.30-0.60 | ≤0.015 | ≤0.003 | 4.80-5.20 | 2.20-2.60 | 0.40-0.70 | 一 |

| DVA-Nb | 0.35-0.42 | 0.10-0.30 | 0.30-0.60 | ≤0.015 | ≤0.003 | 4.80-5.20 | 2.20-2.60 | 0.40-0.70 | some |

Technical service for Tool and die steel DVA/DVA-Nb

Vacuum heat treatment and surface treatment of mold .Oxynitriding ,carbonitriding ,carburizing and nitriding .

Tool and die steel DVA Recommand heat treatment

| Hear temperature/℃ | Cooling way | Hardness (HRC) | Tempering Temperature/℃ | Tempering Times | Hardness (HRC) | ||

| First preheating | Second preheating | Last preheating | |||||

| 500-600 | 820-860 | 1010-1030 | oil cooling | 53-55 | 560-620 | 2-3 | 50-46 |

Tool and die steel DVA property

Tool and die steel DVA application

It is widely used in die-casting mould ,hot extruding die ,brass casting die ,hat-forging dies etc.

Other Tool and die steel we provided

| Catalogue | Grades | Size | |

| Diameter (mm) | Thickness*width (mm) | ||

| Plastic mold steel | S50C,S55C,S55C+Cr,HMSD2738,HMSD2738HH,P20, | Φ200-1200 | 160~1000×300~2000 |

| 4Cr13ESR,S136ESR,HMSD NAK80,1.2083,1.2316,1.2711,1.2714,1.2767 | Φ100-450 | 100~450×300~2000 | |

| Hot work die steel | HMSD 2344/PH13,HMSD DVN,HMSD DM,HMSD H13-MOD | Φ100-450 | 100~450×300~2000 |

| 1.2344/H13 ESR,1.2365/H10 ESR,1.2343/H11ESR,1.2367,3Cr2W8V/H21 ESR,5CrNiMo,H13F,SKD61 | Φ100-1000 | 100~600×300~2000 | |

| Cold work die steel | 1.2379/D2 ESR,HMSD DC53,SKD11,Cr12MoV ESR | Φ100-350 | 100~350×300~1000 |

About Guangda for die and tool steel

Guangda are professional die and tool steel manfuacturer and based on professional technologies,well-furnished equipmnets with rich experience. We provide high quality die steel materials: super large section pre-hardening plastic die , high polishing mirror die , high polishing mirror die , corrosion resistant mirror die , car lamp die steel, high heat strength hot die steel , high heat stability hot work die steel etc .

We are qualified by the classifications such as PED,DNV, BV, Rina, ISO, GL, ABS, LR .Act as the high-tech enterprises with high-quality special alloy materials as the core business belong to the "advanced iron and steel materials" industry under the strategic emerging industries supported by the state.

Products are widely used in automobille,machinery and electronics industry , home appliances ,defense and aerospace industry .Especially , the newly developed die-casting mold steel ,core bar for large diameter steel sleeves and big plastic mould block ,have filled in the technical blanks and reached the top quality in the world .At the same time ,we maintain leading role in advanced vacuum heat treatment technology and advanced surface technology with the support of the research Group .

Smelting

Forging

Heat treatment

Machining

Stock

DVA steel

hot work steel

tool steel suppliers